Ugly duckling, it's over!

In 1989, when I arrived in Espírito Santo to work on the expansion project of ArcelorMittal Tubarão, then known as CST, I was shocked professionally. I had come from Pernambuco, where I had worked in an industrial complex, including an equipment factory, a steel and iron foundry and a steel mill for the production of rebar.

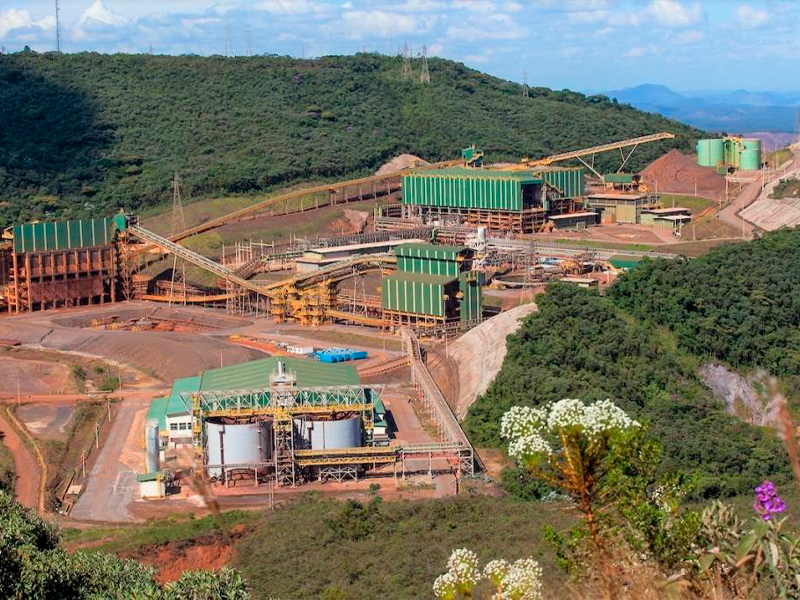

Here in the state, despite the presence of large companies such as Suzano (then Aracruz Celulose), Samarco, Vale, ArcelorMittal Tubarão and Petrobras, the supply chain that served these industries was incipient, without any tradition, and the labor force was undervalued. They told me, jokingly, to be careful with MOCA – labor force from Espírito Santo – that has neither qualifications nor commitment.

When I traveled for work to other states and said that I was living in Espírito Santo, I received suspicious looks, as if I were regressing. They put us in an inferior place as if we were the UGLY DUCKLING of the southeast region.

All of this intrigued me. My human (acquired from my parents) and professional (I had worked on several projects in different regions of the country and the world) background did not allow me to accept this situation. I understand that every person, regardless of color, gender, age and background, has a skill, depending on the opportunity they are given.

Within this context, with the support of friends I made here and of class entities in the industrial sector and related areas such as Sindifer, Sinduscon, CDMEC, Sebrae, Bandes and Findes, we began work to identify supply opportunities for large companies and at the same time we evaluated local potential.

Working in a planned and organized manner, with monthly monitoring of the actions carried out through the PDF – Supplier Development Program of Espírito Santo, we began to achieve results. At first, there was distrust, but the business owners believed in the purpose and realized that they needed to prepare themselves to compete and grow sustainably. With support from the government, Sebrae and Senai, the workers participated in training and qualification courses, including aspects of safety and the environment.

Additionally, national and international trips were organized for executives and businesspeople to acquire knowledge and establish partnerships, always with the support of entities and investors. Technical seminars, technical and business meetings and trade fairs were then held.

One of the most successful events is MECSHOW, which will take place on August 2, 3 and 4 in 2022. The event, which is celebrating its 15th anniversary, was initially held to bring suppliers closer to the local market. Today, it is respected nationwide, and is the ideal place for networking, equipment exhibitions and discussions on technology, investments and business, with the participation of companies and executives from several Brazilian states and other countries.

Our companies currently work nationwide on steel, mining, pulp and paper, and oil and gas projects, with recognition from our clients. Our professionals are a reference in several specialties and are respected by our partners. We are welcomed with joy, demonstrating the strength of our companies, our workers, and the state of Espírito Santo.

UGLY DUCKLING, IT'S OVER!!! With humility, training and work we will still do more. Alone we go faster, together we go further.